If you’re putting on your hat and cowboy boots to visit Texas for the AFS show – yeeeah!! – send us a quick e-mail (info@solutionsfonderie.com) ! We’ll schedule a kick-start discussion with our metallurgist to support your growth in 2018. Here’s what will be hot at SF stall #111 this year but first, how do we add value to your business ?

If you’re putting on your hat and cowboy boots to visit Texas for the AFS show – yeeeah!! – send us a quick e-mail (info@solutionsfonderie.com) ! We’ll schedule a kick-start discussion with our metallurgist to support your growth in 2018. Here’s what will be hot at SF stall #111 this year but first, how do we add value to your business ?

SF is your partner of growth whether you’re a casting buyer or a foundry. At the AFS show this year, our value offer will focus more on foundries. It has two main lines:

-

R&D for SF technologies based on challenges foundries shared with us (see thermal analysis and casting defect app solutions by SF);

-

Distribution and service in Canada&USA for leading manufacturers’ equipment, here we go :

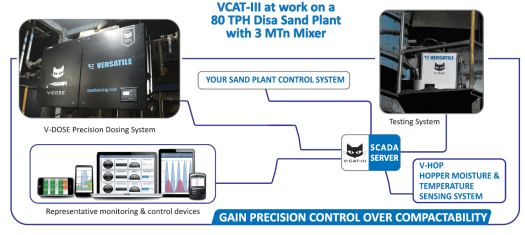

VERSATILE SAND TESTING ( click here to download brochure)

Contact us to receive the complete paper catalogue of Versatile equipment or visit www.sandtesting.com

We import and calibrate Versatile Sand Testing equipment at our office in Québec, Canada. Our metallurgists love foundry sand so let’s talk !

We import and calibrate Versatile Sand Testing equipment at our office in Québec, Canada. Our metallurgists love foundry sand so let’s talk !

MELTLAB & SF THERMAL ANALYSIS TO CONTROL POROSITIES IN ALUMINUM ( contact us for more info )

Since 2016, SF is developing this new porosity prediction tool in Québec, Canada for melt quality at your aluminum foundries. It is supported by MeltLab thermal analysis technology ( see www.meltlab.com ) . For high value castings you need to measure your melt properties. Let’s schedule a demo to measure your melt quality and stability from one batch to another, you’ll be surprised !

Here’s an article we posted previously on the state of art for aluminum melt cleanliness :

METAL PROTECTION LENOLI ( click here to visit website )

Based in beautiful Québec, Canada, Lenoli metal treatments & anodisations have been purpose tested and proven to greatly reduce the rate of corrosion of metallic parts, instruments and surfaces by up to 200%. Surfaces treated do not have to be re-treated or painted for up to 15 years a time.

ATOM WELDING ( click here to visit website )

An easy way to repair your non-structural casting defects using this cold welding technology.

ATOM also has a great welding solution for thin stainless steel & aluminum sheets.

PROSSERGY ( click to download brochure )

We’re making the focus on Prossergy metal fiber burners for your foundry. Thanks to a high exchange by radiation, and higher efficiency than conventional flame burners (up to 40% of the fuel power), it is preferable for :

- Homogeneous heating temperatures

- Energy saving compared to conventional flame burners

- The possibility of reusing some off-gas foundry

CASTING DEFECT APP ( click here to visit website and download )

Download the free version on your mobile phone now. Subscribe to our blog or newsletter to keep current with the upcoming new version we’re working on. You’ll take photos and archive your own casting defects per part #, per shift for solutions specific to your foundry.

Contact us today for more info or see you in Texas next week. The upcoming article on SF blog will be for casting buyers. We’ll underline the main challenges you face as casting buyers, some of which we wrote in this article published in the new magazine called Parts Buyer Authority ( you can view it by clicking here )

Surbscribe to our blog today and let’s grow together.

The SF team